Bamperer machine - This is a large -scale entertainment equipment. Equipment includes bumpering cars and an indoor arena. There are panels on the ceiling or floor, working from electricity (Or from batteries). There are small electric bumper machines, which passengers can ride. The attraction "Avtodr" is surrounded by a rubber apron and connected to the floor for supplying electricity. There is usually no more than two people in the car, There are pedals to accelerate and steering wheel for control.

Players will drive bumper cars in a circle in the room. They give pleasure, pursuing and encountering each other. Gameplay fascinating and exciting, It is well accepted by the market and loved by the players. Suitable for use in picturesque places, on playgrounds, In the parks, Square, supermarkets and other places.

Currently Our company has three bumper machines with different electric drive modes. This Bamperer cars with an upper back, Bamperer machines with a ground grid And Bamperer machines with a battery.

This is a type of bumper car. In the rear of the car there is antenna, connected to the ceiling. There are several conductive strips on the ceiling, which can provide electricity. There are no special requirements for the soil used, The main thing, so that it is even and smooth.

As follows from the name, This is a kind of entertaining equipment, which uses the Earth to conduct electricity, which contributes to the operation of bumper machines. Therefore, to the ground, where it is used, Certain requirements are presented. It is required to lay specialized floors. Safety level slightly higher, than the bumper vehicles Skynet.

Bampering machines with a battery is high -tech products in the bumper car industry. Works for batteries and has high safety indicators. There is no need to install a skynet or floor, The requirements for the place of use are small, And the initial investment costs are small.

Our process of manufacturing bumper vehicles.

Usually we use for you a package from fiberglass. To fiberglass add the reinforcing material fiberglass. Fiberglass is inorganic fibrous material, elongated or blown out of molten glass. Its strength in 2 times higher, than steel. Wear -resistant, Resistant to clashes, High level of security, He can also extend the service life bumper car, which you buy.

What material do we use for the cavalry case?

We are a professional manufacturer of entertainment equipment. Our process of manufacturing bumper cars is a process, in which technical accuracy and individualization are ideally combined in accordance with the needs of customers. Through the use of advanced engineering planning and 3D modeling technologies. To ensure the reliability of the design of the bumper body and the electric system for you. When choosing materials We insist on using high -strength, Environmentally friendly and shock -resistant materials. And each component is precisely made using laser cutting and processing technology with CNC. In the assembly process, we adhere to strict quality control procedures. Make sure, that each of your bumper machines is thoroughly assembled and strict safety trials.

Our electronic control system is specially designed to ensure simple and safe operation. At the same time, we also provide you with individual services. Various options are available, including topics, Colors, Patterns and sizes of cars, To satisfy your specific needs. Our goal is not just to produce durable and safe bumper machines. Also make sure, that they provide your visitors with unprecedented entertainment. Thanks to our painstaking skill and a service oriented to the client We proudly supply high -quality bumpering machines to entertainment parks around the world. And are ready to become your reliable partner.

The price of the majority bumper machines per unit 60 000 to 100 000 rubles. When buying several bumper cars, discounts are provided together. In the square 100 square meters can be used five bumper machines, Maximum six.

The cost of creating an indoor circuit with bumper machines In Russia, in places with high patency of people, it includes the cost of renting a premises, The purchase of equipment, Repair and so on. Here is an approximate assessment of the main costs:

- 1The cost of renting a site. Depends on the location and size of the site. For example, The rent in the center of Moscow is very high, Maybe, more 100 000 rubles a month. In small cities or suburbs, it can be much cheaper.

- 2Buying bumper machines and related equipment. The price of one commercial machine can vary from 60 000 to 100 000 rubles depending on the manufacturer, functions and quality. If you plan to buy 10 cars, then this can do from you from 600 000 to 1 000 000 rubles.

- 3Decoration and preparation of the premises.

Includes floor styling, decor, lighting, Sound system and other necessary amenities. The cost can vary from tens of thousands to hundreds of thousands of rubles, depending on the complexity of the design and quality requirements. - 4Security measures.

Including insurance, Fire measures, Emergency exits, video surveillance, etc., which also entails additional expenses. - 5Licenses and insurance for doing business.

It is necessary to calculate in accordance with the specific rules and norms of Russia. - 6Advertising and marketing for opening.

Depending on your marketing strategy, additional costs to attract customers may be required. - 7Service and salary of employees.

Everyday operating expenses, Including the repair of equipment and wages of employees.

All in all, for creating an indoor circuit medium -sized with bampery machines in places with high perpetability of people in Russia. The initial investments can be compiled from 7 millions to 30 millions rubles and even more. This is a very approximate assessment, And the exact cost should be determined on the basis of detailed planning and market research of a particular project. It is recommended to consult local business consultants and architectural specialists to obtain a more accurate budget and planning before starting work.

Properties fiberglass make it the perfect material for production of entertainment equipment, such as Bamperer machines. Its high strength and durability guarantee, that the equipment will withstand multiple clashes and various Climate Conditions for long -term use. Light properties simplify transportation and installation. And plasticity allows us to create a unique and attractive form of a bumper car for you.

Insulation and fire resistance of fiberglass increase the safety of entertainment equipment. And low maintenance requirements and ease of cleaning reduce long -term operating costs. The use of fiberglass for the body of your bumper car in the long run will become an economically effective way for you and for us.

Below are some floors care instructions bumper cars. Hope, They will help you.

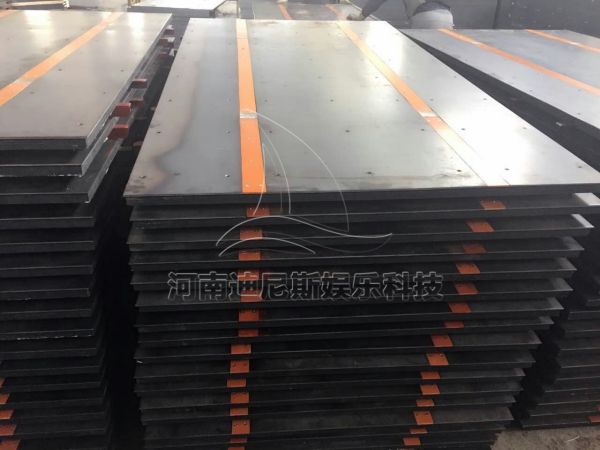

Machines bumper lower backdrop Paul is a wooden structure + Steel plate. Proper maintenance can significantly extend the service life of bumper machines. First, What do you need to do, This is waterproofing the floor. If the floor is getting wet, Remove it in a timely manner. Do not allow rot carrying wood and rust of steel plates.

You need to check the floor screws and screw screws every day wiring. If there is any weakening, they should be strengthened in time. At the same time, dust and garbage should be removed from the floor. Pay special attention to that, that there should not be metal items on the floor, To prevent a short circuit on the floor and damage to electrical appliances.

Check every day, Are there any cracks in the soldered floor joints. If there are cracks, they should be repaired and polished in time, to ensure the normal operation of the bumper machine.

Approximately every two months or when the floor gets wet, It should be thoroughly washed. First wipe the dust, and then wash the floor with diesel fuel or kerosene. The main goal is to remove pollution and prevent the appearance of rust to ensure the normal operation of the bumperer machine.

Bamperer cars on batteries Charging time on our factory It occupies about 6-8 hours. After complete charging He can work about 8-10 hours.

Here are three things, which should be paid attention to during daily inspection and maintenance:

The first step - open the back panel of the bumper and check, Whether the wiring is connected Bamperer cars on batteries To brake blocks. Examining the wiring of the car bumper, Remember, that don't pull too fast, In order not to break a thin wire. Then turn the car and check, Are there any road parts by car. If the wire is disconnected, Weakens or damaged, Grounding may occur. Therefore, you should carefully check during a daily inspection.

Pay attention, that some manufacturers bumper machines For security reasons, all wires on the production line are disconnected before, how bumper cars will leave the plant. Ensure the safety of bumper machines during transportation.

The second step - check, that all equipment is safe and works properly. You need to check these amenities, including, Among other things, The main power switch, Installation of time, Launch of the bamperer machine, pressing the control switch to handles, as well as driving and stopping the vehicle.

The third step - check, Is the battery discharged, and then charge it. Charging time is at least 6 hours and no more 12 hours. During charging, it is necessary to monitor that, so that there are no dangerous objects nearby, To avoid other accidents. And there is no need to put the battery in the car when charging, In order not to cause a fire. The battery is heated during charging, Therefore, you need to open the car cover, to provide good ventilation during charging. Be careful, Do not fold a few chargers together.

Skirt bumper car with floor the grid should take into account stability, Durability and good electrical conductivity. In the design of the floor of the bumper car, produced by our factory, As a supporting base, a wooden structure is used, and steel plates are used as the upper structure.

- Wooden supports are usually made of strong wood. For example, hard wood or processed pine. These materials should withstand weight, and also have some resistance to a humid environment.

- The supporting structure may consist of several wooden beams, crossing the design. They form a lattice frame, which provides a strong base for steel panels.

- The support layers of wood are also developed taking into account ventilation and drainage, To guarantee, that water or moisture does not accumulate under the floor. Keep the structure dry and resistant to corrosion.

The upper layer of the steel plate:

- Steel The plate is an important part of the conductive layer. It should not only have excellent electrical conductivity, but also should be strong enough, to withstand the collisions of vehicles and the actions of passengers.

- The surface of the steel plate can have anti -slip processing for additional safety. It is also covered with anti -corrosion coating, to extend the service life of the floor.

- Steel plates are connected by welding or bolts, to ensure the continuity of the entire floor structure. In the conductive zone there will be accurate insulation and wiring, forming a complex network, by which the car will receive electricity.

Conducting system:

- Usually under the floor there is an isolation tape to divide the positive and negative poles in order to avoid short circuits, caused by direct contact. The bumper machine receives energy by contacting the conducting areas with alternating positive and negative electrodes through the device for receiving energy at the bottom.

- To ensure safe and reliable power supply into steel plate structures, insulating materials or insulating gaskets can be built -in, used between conducting and non -conducting areas.

The entire floor structure is fully consistent with the current standards and safety rules, including the requirements of electrical safety and fire protection. You can be calm. Besides, Daily care for the floor is important. You will need to serve it daily, To guarantee, that he is always in good working condition. In addition, you will need to conduct regular checks of a wooden structure and steel panels, as well as testing the mains. Ensure stability and security of the power supply system.